�ڶ����֣����δ���ϵ������������������ѹ�ϵ��δ�������

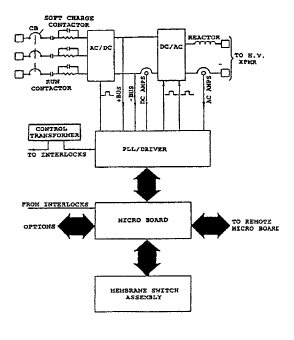

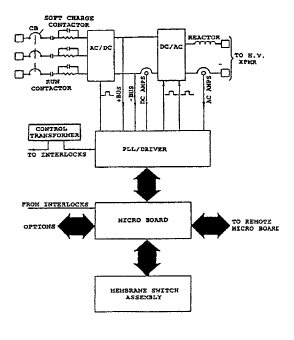

ͼ3������ͼ

ͼ3������ͼ

���еĵ��δ����豸��Ҫ��װ�ɿ��Ƶĵ繦�ʵ�Դ����ѹ60���ȵ�Դ����Ӧ�������豸���������Ƶ�ʡ����ָ�Ƶ��Դ��������һ����ѹ�������ӵ�ѹ����ѹ����Ƶ������

�����ȡ������Ϣ

ͼ3������ͼ

ͼ3������ͼ���еĵ��δ����豸��Ҫ��װ�ɿ��Ƶĵ繦�ʵ�Դ����ѹ60���ȵ�Դ����Ӧ�������豸���������Ƶ�ʡ����ָ�Ƶ��Դ��������һ����ѹ�������ӵ�ѹ����ѹ����Ƶ������